FMG Iron Ore Case Study 1

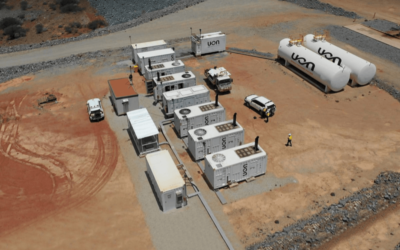

at6 MW POWER STATION 11kv

BACKGROUND

The FMG magnetite iron-ore mine was a new trial mine. UON was awarded the following works:

- 16 MW D&C Power Station for the OHP

- 2 MW D&C power supply for the CHF

- 1 MW BOO village power station

Team Members

Pieces of equipment

Hours worked LTI-free

MW Installed

Pilbara

Region

FMG

Client

IRON ORE

Commodity

D + C / Boom

Contract

KEY SUCCESS

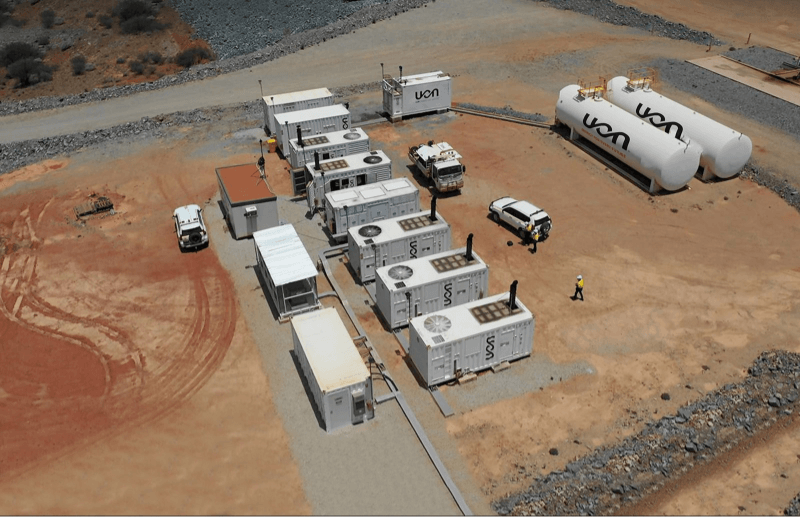

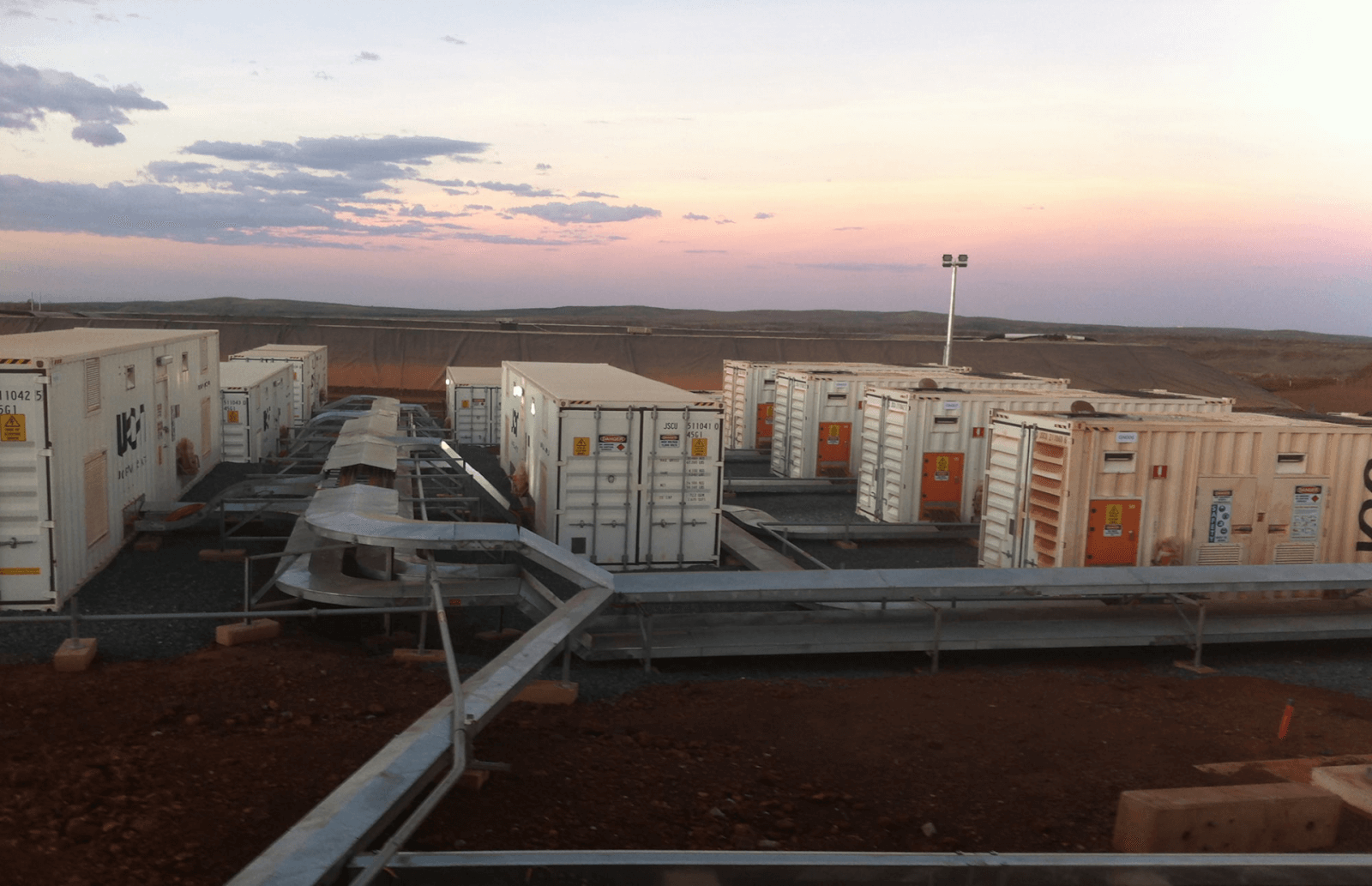

To Design, Construct, Operate and Maintain a 16 MW / 11 kV Diesel Power Station for the FMG Magnetite Project Stage 1.

DELIVERABLES

- 5 x UON PP2000 1.6 MW modular diesel generators

- 8 x UON PP1250 modular diesel generators

- 11 x 415V / 11 kV containerised step-up transformers

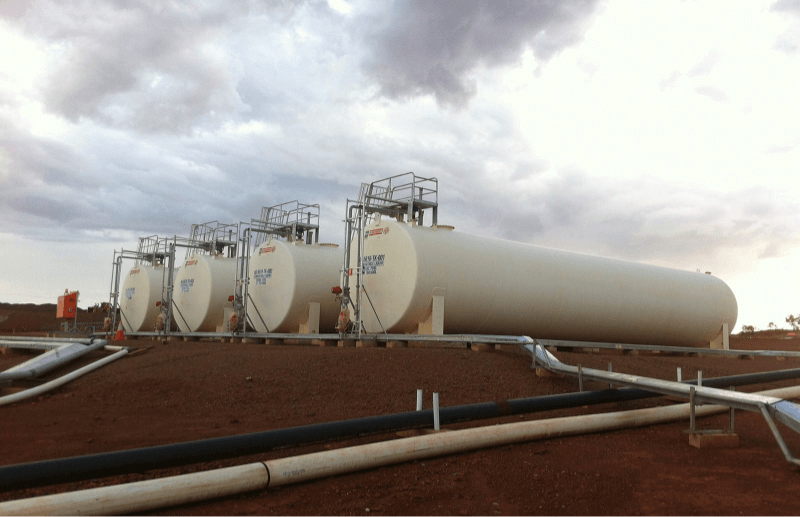

- 600,000 L fuel storage facility with unloading and transfer pumps

- Containerised 11 kV switch room and separate control room

OTHER PROJECTS

Novo Gold Case Study 1

Supply and Installation of Power Station for Underground Mining

Dacian Gold Case Study 1

The key success of the rapid-deployment 6 MW / 11 kV power station was the modularization and flexibility of all equipment provided as part of UON’s complete solution

Bellevue Gold Case Study 1

UON were tasked with delivering a dewatering solution for an old mine being reactivated, via an existing ventilation shaft.

Adaman Gold Case Study 1

UON was contracted to design, manufacture and install a pontoon system to dewater over 7 Billion litres from an old open pit mine.

BHP Case Study 3

The key success of the Rapid-Deployment 30MW Power Station was UON’s time management and orchestrated scheduling of people and plant.

BHP Case Study 2

UON were tasked to Supply, Manufacture and Install Major Dewatering Works and Transfer System.

GET A PROMPT RESPONSE

"*" indicates required fields